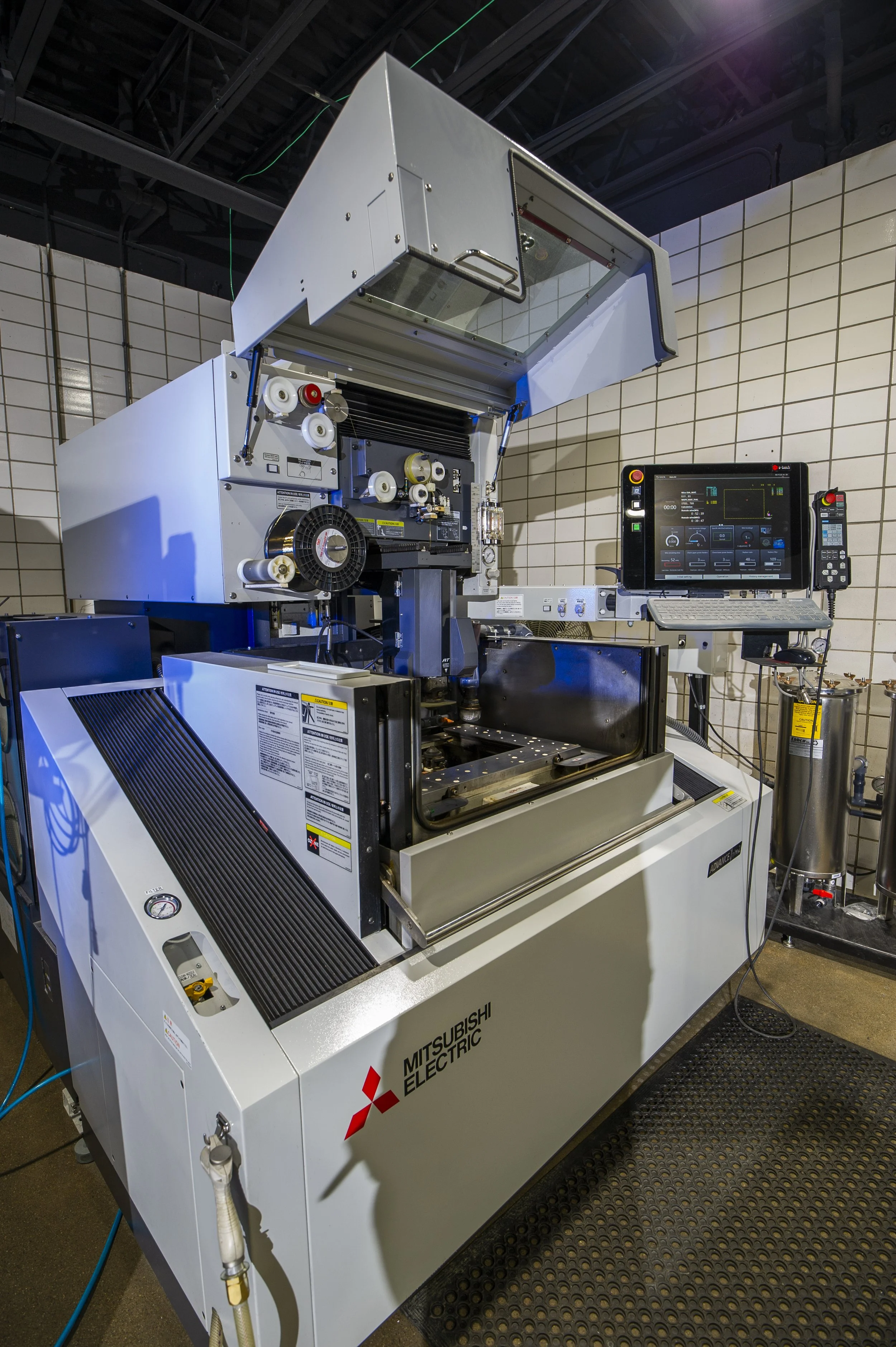

One of the Largest EDM Machine Shops in Dayton OH

Electrical Discharge Machining (EDM) allows us to produce intricate shapes and ultra-precise cuts that traditional methods can’t achieve. This process removes material using controlled electrical discharges, making it ideal for hard metals, tight tolerances, and complex geometries.

-

Used for precision contouring and intricate profiles in hardened materials. Ideal for tooling, molds, and components that demand extreme accuracy and fine surface finishes.

-

Shapes internal cavities, deep pockets, and blind holes that can’t be reached by conventional cutting tools. Perfect for prototypes, die components, and custom production parts.

-

Creates micro and starter holes with pinpoint accuracy — essential for threading wire EDM operations, coolant holes, or small-diameter openings in hard materials.

-

EDM allows tolerances within ±0.0001" and produces detailed internal or external features with clean edges and repeatable accuracy, even in the toughest alloys.

-

Works seamlessly on hardened steels, carbide, titanium, Inconel, and other conductive materials — maintaining structural integrity and surface precision.

-

Because EDM is a non-contact process, there’s no cutting force, reducing the risk of material stress, warping, or tool wear.

-

From one-off custom parts to repeat production, EDM offers speed, consistency, and dimensional stability across all quantities.